Porcelain Insulator News

by Elton Gish

Reprinted from "Crown Jewels of the Wire", March 2002, page 4

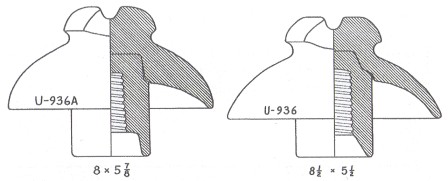

Very little was known about U-936 when an unmarked specimen was reported by

Evelyn Anglin in January 1973. Jack Tod was aware of this 2-part glazeweld style

from the 1907 Thomas catalog, but the illustration in the catalog was not

sufficient to make a drawing for the U-Chart. It did not appear in their 1904

catalog and obviously introduced around 1907 with catalog number 2013. All the

other glazeweld styles that were shown in the 1904 catalog were given new

4-digit catalog numbers, too. U-936 could be ordered with either a 1" or

1-3/8" pinhole and it was designed to be used for up to 25,000 volts. The

Anglin insulator had a 1" pinhole, and I believe all the U-936's located so

far also have a 1" pinhole. When we did the survey of about 30 porcelain

collectors for the Value Guide, 8 unmarked U-936's were reported and only one

with an incuse THOMAS marking on the ear. Later it became obvious that these had

been found in the southern California area.

A couple of years ago Mark Johnson

found three U-936's on the same pole in southern California! Two were unmarked

and one had the THOMAS marking on an ear. However, Mark said that one of the

"U-936's" was different. It was in fact a fraction taller and a full 1

/2" smaller in diameter. And the top skirt was much thicker! Mark shipped

the insulator to me for closer inspection (thanks Mark!!) and to make the

drawing for a new U-number. It has been assigned U-936A. It is unmarked but

definitely a 2-part glazeweld made by Thomas. I feel sure U-936A was made after

U-936 because the skirt is so much thicker. Even though U-936A is smaller, it

weighs essentially the same (2-3/8 lbs) as U-936 due to the-thicker skirt. When

U-936 was introduced, thick porcelain was difficult to make. Boch was granted

the 1898 patent for Thomas' "glazefilling" process, which produced

larger insulators by fusing two or more thin shells. Only Imperial had the skill

to make thicker porcelain although it was fraught with large air bubbles. Insulators made

with the glazewelding technique was continued by Thomas in their 1907 catalog,

but soon dropped in favor of using Portland cement to hold shells together.

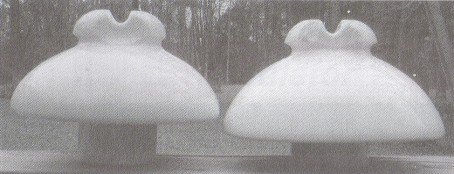

A photo by Mark Johnson shows the U-936A

still in service. It is in the

middle, and

notice the porcelain high voltage sign.

U-936A (left) and U-936 (right)

U-936A (left) and U-936 (right)

A new manufacturer of pin-type porcelain insulators has been discovered, but

I do not know of any specimens that have been confirmed as having been made by

them. I need your help in identifying specimens that may have been made by

this company. The company is Davidson Porcelain Co. of East Liverpool, OH. I

located one undated catalog for this company and one 1918 catalog for Davidson

& Stevenson Porcelain Co. According to Jack Tod's book, Electrical

Porcelain, the plant was located on the north side of Newell Rd. at Corporation

Line, Newell, WV, but they used an East Liverpool mailing address. East

Liverpool was across the Ohio River and the center for porcelain manufacturing.

Photographs of the factory indicate it was located in Chester, WV, which is a

couple of miles east of Newell.

Abandoned factory of The Davidson Porcelain Company.

The Davidson & Stevenson Porcelain Co. was founded in 1913 (catalog says

1914) to make specialty porcelain (non-pin-types). They leased another pottery

plant at the northeast corner of Broadway and 6th streets in East Liverpool from

1913 to 1919. This plant reverted to Hall China Co. in 1920. When Stevenson left

the company in 1920, the name was changed to The Davidson Porcelain Co. Operations were suspended in 1936. They primarily made specialty porcelain

(knobs, cleats, spools, etc.). Insulators from the earlier operation were

embossed "D & S", "D & S P Co.", "EVER

READY", or "EVER READY / D. P. Co.". The specialty porcelain

insulators would have been made of dry process porcelain.

The 1918 catalog does

show six pin-type insulators for low voltage and distribution service up to

10,000 volts. The illustrations are I an upwardly tilted profile to show the

inner skirt, so a possible unique profile is not obvious. The six styles are

exchange, pony, signal, two cable-tops, and a beehive. There is no indication

that the pin-type insulators were either wet process or dry process. It stands

to reason that if they had been made from wet process, the catalog would have

noted such to make them stand out among the many styles of dry process specialty

porcelain. D & S could be the mystery company who made the dry process U-151 A with unique, often black and tan, shiny glaze. The dimensions and

upwardly tilted profile match exactly! It should be noted, too, that Thomas (a

neighbor to D & S) made several small low voltage styles during this same

time period of dry process porcelain.

The undated catalog of The Davidson

Porcelain Co. (Bulletin No. 131) offered a completely modern array of double and

triple petticoat insulators along with the basic smaller styles. Nowhere in the

catalog does it mention that they were made of wet process porcelain but I am

sure they were. The various triple petticoat styles would not have provided

satisfactory results if they were not wet process. Another indication is a guy

insulator was offered in either wet or dry process, which implies that all other

insulators in the catalog were wet process.

The Davidson "high tension

porcelain" insulators had a very unique and distinctive profile totally

unlike those made by any other manufacturer. Please review the six styles shown

here and see if you have anything similar in your collection. I would like to

identify at least one style so we can begin to identify characteristics that

would help to identify other commonly styled insulators made by D & S.

Davidson claimed their "Balanced Design Insulators...have been styled

not to be different in visual appearance but primarily to provide greater

physical strength." In addition, "The graceful lines of Davidson

Porcelain Insulators have other useful features. They are self-cleaning. Soot

and dust will be washed off with every rain. The lineman has greater freedom in

making ties. There is no likelihood of the cable slapping the porcelain

skirts." They conclude with, "They are manufactured carefully from

only the best raw materials obtainable, and under the supervision of experts for

an important service. They are not cheaper - but better - and last longer."

The unique profiles of these six insulators should make them easy to pick out

from the crowd. Note the straight skirts extending down at a 45-degree angle and

the unusual profile of the smallest cable-top. If Davidson did make these

insulators for several years that closely match the catalog illustrations,

surely some have survived and have found their way into collections. Again, let

me know if you have something close to one of these.

|